Delaware Valley Corporation maintains a family-owned heritage of providing custom-designed Non-woven fabrics for the automotive, industrial, marine, medical, construction, RV, and truck & bus industries. We have experience in fashioning automotive Needle-punch Non-woven carpet and other automotive non-woven solutions dating back to the early 1960s. Our automotive non-woven textiles have made their way into multiple GM, Chrysler, and Ford platforms such as the Buick Lacrosse, Cadillac Escalade, Chevrolet Impala, Chevrolet Silverado, Chrysler Town and Country, Dodge Caravan, Ford Econoline, Ford Navigator, Pontiac Grand Prix, and others.

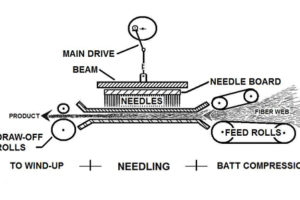

Automotive Fabrics are only one aspect of our portfolio of non-woven and needle-punch textiles, though they have been instrumental in developing our rapid response mentality and custom design non-woven fabric knowledge base. Our Textile Design group, commitment to innovation, and cost-conscious approach to Needle-punch Non-woven fabric and felt manufacturing, enable us to produce a wide range of popular and useful industrial and consumer fabrics. The beauty of the non-woven fabric industry is flexibility…. the ability, with innovative thought and the proper selection of raw materials, to be able to produce a wide variety of end products for un-related industries. Non-woven fabrics can be engineered to perform functions as varied as heat insulation tiles for the space shuttle to carpet cushion underlay and from dermal medical wraps to wall coverings. This flexibility is the key to success in our ever-changing world, and Delaware Valley embraces the opportunity to work with forward-looking customers to design custom non-woven fabrics to meet these ever-changing current and future needs. We can supply non-woven fabrics as components or finished products to end uses as varied as:

Auto/Truck/Bus/Marine…. floor mats, seating fabrics, trunk and cargo compartment liners, hull and wall liners, ceiling fabrics, and fender covers.

Home/Building ….carpet and rug underlay, entry mats, runners, carpet tiles, area carpeting, wall coverings, furniture floor slide/protectors, lally column coverings and roofing felts.

Recreation…..putting green mats, barbecue mats, pool cover edge protectors, gun safe and case liners, turf field drainage, and sideline matting.

Industrial…fatigue matting, oil absorption, vinyl substrates, and fluid transfer.

Delaware Valley continues to look for new uses of our non-woven fabrics, and we look to you, our customer, for new direction.