Delaware Valley Corporation Needle Punched Textiles

For over seventy years, Delaware Valley Corporation has been a trusted manufacturer of high-quality needle-punched textile products. We serve a wide range of industries, including automotive, construction, medical, roofing, and more. Our team is dedicated to providing our customers with the best possible experience, and we’re always working to improve our products and services.

We offer a wide range of products including carpeting, filtration, abrasion prevention, acoustic control, and many more. Our products are made with the highest quality materials and craftsmanship, and we stand behind our products.

What is the Process of Needle Punching?

Needle-punching textile technology is a process of interlocking staple, textile fibers together using barbed needles. This creates a strong bond within the fabrics, which can be used for various applications such as carpeting, acoustic insulation, filtration, and soil stabilization.

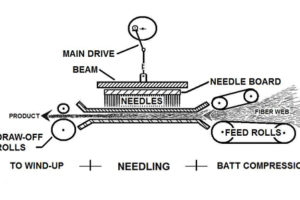

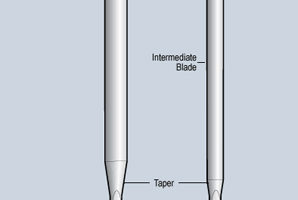

The automated, needle-punch process starts with bales of “Staple” fibers (individual fibers cut to specified lengths). The fibers in these bales might be made of different materials, different colors or varying diameters (denier) depending upon the application of the final product. The bales are opened and the fibers mixed as required. The loose fibers are then “Carded” (combed) into a uniform “Web” which is “lapped” over itself several times to achieve a loose, continuous web of the desired loft, density and weight. This web is then penetrated many times with barbed needles that push the upper layers of fibers through the lower layers, thus interlocking them to achieve the thickness, strength and surface texture of the finished textile. The style of the barbs in the needles, the penetration density and the depth of penetration are all determining factors in the visual characteristics and strength of the fabric and can be easily modified to create numerous products from the same original “Web”!

Applications of Needle-Punched Materials

Since their invention in the early 19th century, needle-punched materials have found a wide range of applications in various industries. Today, these versatile materials are used in everything from filters and insulation to upholstery and automotive interiors.

- Abrasion Prevention: The needle-punching process creates a strong, durable fabric that can withstand wear and tear. This makes it ideal for use in high-traffic areas or for items that will see a lot of use, such as carpeting or boot linings.

- Thermal Insulation: Needle-punched materials can be used to create effective thermal insulation. This is because the needle-punching process can produce fabrics with a high loft, which helps to trap air and prevent heat loss.

- Acoustic Control: Needle-punched materials can also help control noise levels. The needle-punching process creates a fabric with a high degree of sound-absorbing properties, making it ideal for acoustic panels or wall coverings.

- Geotextiles: Needle-punched fabrics are often used in geotextile applications. In this usage, the fabric helps to reinforce soil or other materials while allowing water and air to pass through. This makes needle-punched fabrics ideal for use in erosion control or drainage applications.

- Automotive: The automotive industry makes use of needle-punched materials in a variety of applications. Needle-punched fabrics can be used to replace tufted carpeting, providing a luxurious look without the weight or cost of traditional tufted carpets.

Why Choose Delaware Valley Corporation for Your Needle-Punched Material?

If you’re looking for a company that can provide you with the highest-quality needle-punched material, look no further than Delaware Valley Corporation. Our team of experts can help you find the perfect product for your needs. Our wide array of custom manufacturing capabilities allows us to create unique solutions for your specific applications.

There are many reasons to choose Delaware Valley Corporation for your needle-punched material needs, including:

- We are a family-owned and operated business.

- Our materials are used in various applications, such as automotive, marine, industrial, and more.

- We offer competitive pricing on all of our products.

- We have a team of experts who are always available to answer any questions and help you select the best needle-punched textile for your application.

We are the leaders in needle-punching textile technology and are proud to offer our products and services to our valued customers.

Contact us today to learn more about what we can do for you.