Delaware Valley Corporation manufactures custom nonwoven fabrics and textiles, specializing in industrial fabrics and carpeting for a diverse range of products. Applications of our textiles range from car floor mats to medical cast wraps and beyond. Our primary concern in our manufacturing process is to meet our customer’s needs by using innovative, needle punch solutions. We welcome non-traditional requirements that may not be able to be fulfilled by most standard textile solutions.

Many of our current products resulted from customers looking for solutions for fabrics that we were able to fulfill with our custom non-woven fabrics. Specific examples of how our custom design approach has benefited our customers include many of our current standard products of today. Our single-ply roofing separator/slip-sheet was the result of a custom design to protect new installations of single-ply PVC and EPDM roofing systems from the old roofing they were to be placed over. This product, with additional custom design then became a standard in protecting these same single-ply membranes in uses for containment ponds and retention basins, and eventually morphed into the geotextile use as filter fabric.

Our Textile Design process for specific customers has also lead to the following custom non-woven fabrics and felts: fluid retention mats, hydrophobic oil absorbers, electrical cable wrap, sound deadening gaskets, breathable vacuum molding liners, saddle blankets, heat and sound insulation blankets, and the list will continue as you, our customer, present us with new challenges. Our creativity and flexibility set us apart from our competitors, and enable us to complete your project efficiently and accurately with an engineered fabric solution that you may never have imagined possible.

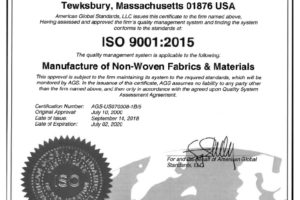

In our dedicated 90,000 square foot production facility comprising 5 production lines, all under one roof in Tewksbury, MA, we needle-punch textiles and fabrics in widths up to 180″ (15′), with fiber denier ranging from 1.5 to 400 and weights from 4 oz to 50 ounces. Our needle punched fabrics are especially suited to industrial applications thanks to features such as fade resistance, stain resistance, fray resistance, abrasion resistance, mold-ability and the ability to be cut in unique and specialty shapes. We are able to control a variety of characteristics including weight, thickness, loft, pattern, stiffness, tensile strength, porosity, absorption and color to name a few. We can provide secondary operations such as Die cutting and adhesive or custom backing as needed. We look forward to the challenges you may have and the opportunity to serve you.